About Us

For nearly 20 years, Aero Machine has been a leading turnkey machine shop in Valparaiso, Indiana and across the Midwest region. The services we typically provide our clients include: Custom & CNC machining, Welding & Fabrication, Millwright, and Field Services. We are specially known for emergency and rush job capabilities as our facility can run 24/7 in order to fully service our clients’ needs.

Our modern machine shop offers custom machining services, vertical and horizontal milling, unmatched turning capabilities and full CNC programmable equipment. Our fabrication shop can weld, bend and finish a variety of materials to meet stringent quality standards. Our ability to disassemble, inspect, repair and reassemble gives us a strong advantage over our competitors. We also offer transportation services to pick up and deliver your equipment to its final location.

At Aero Machine, our team of machinists undergo extensive training to gain the knowledge and experience necessary to operate at 100% precision. With our skilled labor force and state-of-the-art equipment, we work together seamlessly to deliver benefits to our clients that are value-based, performance-based and leadership-driven. We foster long-term relationships with our clients by providing solutions over 24 hours a day and 7 days a week.

Over the course of our existence, we have completed over 150,000 jobs and projects for our clients that are principally within the Steel, Manufacturing, Energy, Pulp & Paper, and Food sectors.

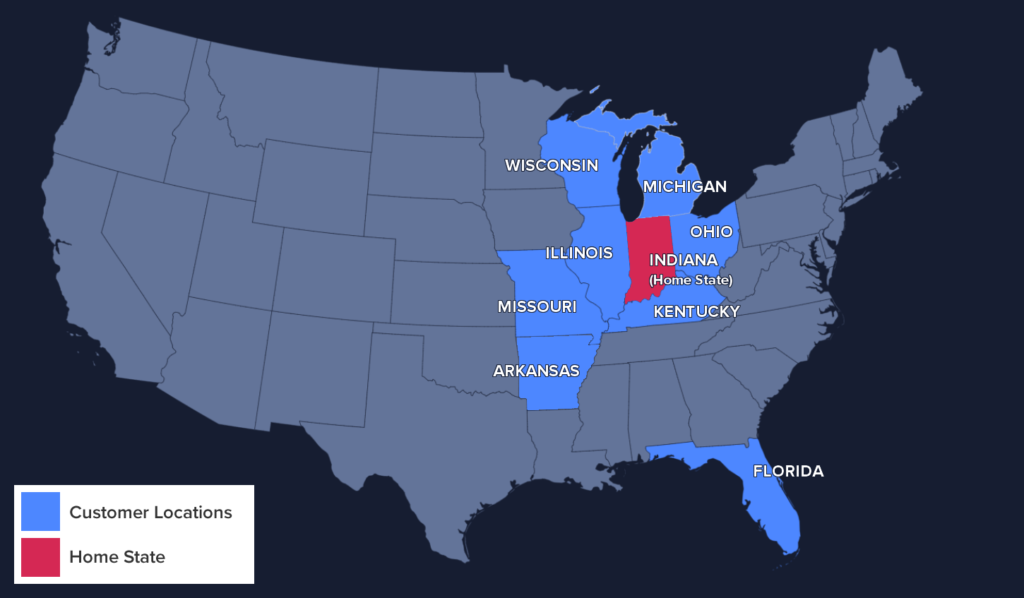

States served: Arkansas, Florida, Illinois, Indiana, Kentucky, Michigan, Missouri, Ohio, Wisconsin

Select Customer Sampling:

Our Values

We understand your business, and therefore, the importance of our services. We strive to make quality equipment for you in order to produce quality products for your customers. Our ambition to help you succeed stems from our emphasis on integrity and trust, which are the foundation of our values:

Partnership: Our relationships with clients, service providers, and employees are the fundamental component to everyone’s success. Our partnerships are built on trust, improvement, fairness and to conduct business in an ethical manner.

Safety: We believe in zero incidents with injury and have processes and controls in places to eliminate hazards in addition to Personal Protective Equipment (PPE).

Quality: We trust in our multiple check points along the machining process to ensure 100% accurate and quality parts are delivered to you. We take pride in eliminating re-work.

Community: We understand the hard working community of Northwest Indiana and are dedicated to working with local businesses and educators to improve our neighborhoods. We maintain relationships with many local professional, educational, and charitable organizations including:

Community Affiliations & Philanthropy

Equipment List Sampling

Aero Machine continues to add new equipment to the facility to provide customers with cutting-edge products and competitive pricing. Below is a select sampling of our equipment:

CNC Turning

- HAAS SL-30T

- 17” Max Turn Diameter, 34” Max Turning Length

- HAAS ST-30LY

- 21” Max Turn Diameter, 62.5” Max Turn Length

- Y-Axis Live Tool Milling Capabilities

- HAAS SL-40L

- 25” Max Turn Diameter, 80” Max Turning Length

CNC Milling

- HAAS VF-3YT/50

- 3 Axis CNC Vertical Machining Center

- 40” x 26” x 25” Travel, 30 hp

- 30 + 1 Tool Changer, 50 CAT Taper

- 4th Axis Rotary Table

- HAAS VF-5/50XT

- 3 Axis CNC Vertical Machining Center

- 66” x 26” x 25” Travel, 30hp

- 30 + 1 Tool Changer, 50 CAT Taper

- 4th Axis Rotary Table

- HAAS VF-6/50

- 3 Axis CNC Vertical Machining Center

- 64” x 32” x 30” Travel, 30hp

- 30 + 1 Tool Changer, 50 CAT Taper

- 4th Axis Rotary Table

Bar Mills

- 2ea. Giddings & Lewis PMC-4

- 4” Table Type Horizontal Boring Mill

- 36” x 72” Table

- 48” x 96” Table

- 4” Table Type Horizontal Boring Mill

- Giddings & Lewis 70-E4-T

- 4” Table Type Horizontal Boring Mill

- 48” x 96” Table

- Giddings & Lewis PMC-5

- 5” Table Type Horizontal Boring Mill

- 48” x 72” Table

Big Lathes

- Poreba Est. 36” x 150” Engine Lathe

- LeBlond 19” x 150” Engine Lathe, 18” Chuck, 3” Hole Through Spindle

- Poreba TR-100 B1/8M 38” x 312” Engine Lathe

- Giddings & Lewis Hypro 62” Vertical Boring Mill

- 2 Swivel Mounted Ram Type Heads

Small Lathes

- 2ea. Fortune Model 1660G 16” x 60” Engine Lathe

- Clausing Colchester Model 13” x 50” Engine Lathe

- Summit Model 19-4, 19” x 80” Engine Lathe